|

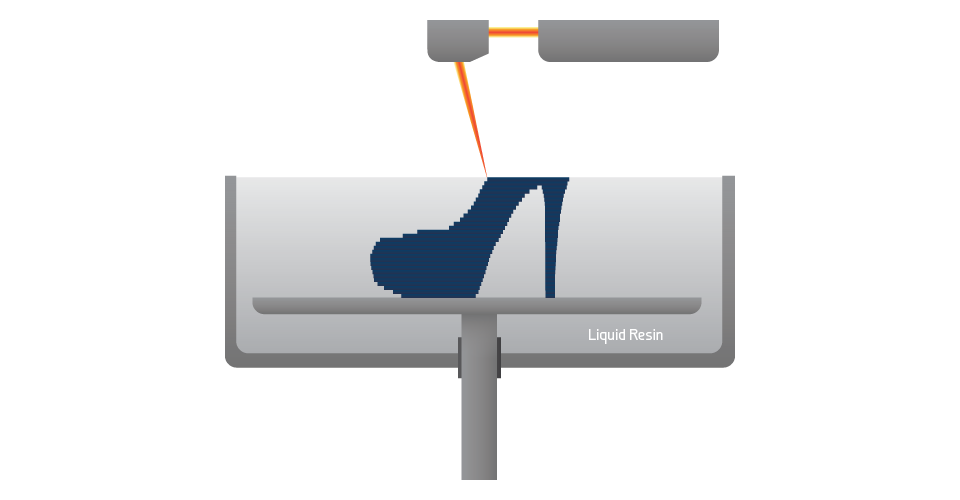

Stereolithography

Similar to polyjet matrix printing, stereolithography is an additive manufacturing process that using the combination of resin and a UV laser to build prototypes one layer at a time. The CAD model provides the data for the laser to trace each cross section on the surface of the liquid resin. The UV laser then heats the resin to a solidifying state, fusing it with the layer beneath. After a layer has been completed, the build tray platform descends so a new layer of resin can be applied. After the build has been completed, the part is then immersed in a chemical bath to remove any excess resin. The final step in the stereolithography process is for the part to be cured in a UV oven. After a pattern has been traced, the SLA's elevator platform descends by a single layer thickness, typically 0.05 mm to 0.15 mm (0.002" to 0.006"). Then, a resin-filled blade sweeps across the part cross section, re-coating it with fresh material. On this new liquid surface the subsequent layer pattern is traced, adhering to the previous layer. A complete 3D part is formed by this process. After building, parts are cleaned of excess resin by immersion in a chemical bath and then cured in a UV oven.

|

|

Specializing in 3D Engineering Solutions, 3D Printing Services (Polyjet , Polyjet Matrix Technology) Fused Deposition Modeling (FDM), Sterolithography (SLA), and Selective Laser Sintering (SLS), our team of certified engineer designers offer engineering design solutions which enables Rapid Prototyping Services Canada to always be strategic and innovative to better your Product Development experience. With the leading edge technology for all 3D Printing, Product design, Product development and rapid prototyping applications, we are competitively priced and always deliver quality results to our clients. With 3D modeling, rapid prototyping, and the latest additive manufacturing technologies, Rapid Prototyping Services Canada believes in delivering value to our clients through meeting budget requirements, timelines, and providing expert consultation. Our customers range from all over the USA and Canada. We also service the following areas : British Columbia, Toronto Ontario, Vaughan Ontario, Markham Ontario, Thornhill Ontario, Richmond Hill Ontario, Concord Ontario, Mississauga, Durham Region, Oshawa, Etobicoke, Cambridge, Brampton, Whitby, Peel, Woodbridge, Barrie, York region, Maple, Aurora, Newmarket, Cambridge, Whitby, Peel, Woodbridge, Barrie, York, Maple, Aurora, Newmarket Ontario and surrounding areas. Nationally we service Vancouver , Calgary , Edmonton, Alberta, Montreal Quebec, Ottawa and Fort McMurray. In the United States we provide rapid prototyping services to New York, Los Angeles, Chicago, Houston, Philadelphia, Phoenix, San Antonio, San Diego, Dallas, San Jose, Indianapolis, San Francisco, Austin, Columbus, Fort Worth, Charlotte, Detroit, Memphis, Baltimore, Boston, Seattle, Washington, Nashville, Denver, Las Vegas, Sacramento, Silicon Valley, Raleigh, Pittsburgh, Portland, Atlanta, Springfield, Scottsdale, Miami, Cleveland, Oakland, Minneapolis, Mexico City, and Washington DC. |